QUICK INFO:

The supplied sensor can be installed in different positions depending on the engine type, convenience and desired accuracy.

When possible, it is recommended to apply the 1st option that produces the most accurate knock detection. Although the

Plex Knock Monitor is compatible with many OEM knock sensors, using the supplied Bosch sensor will yield the most consistent results.

KNOCK SENSOR

CONNECTOR PIN OUT

yellow: knock signal

black: cable screen

blue: signal ground

Knock Sensor connector: Bosch brand, D 261-205-359-01

ALTERNATE LOCATIONS FOR KNOCK SENSOR INSTALLATION

1. In the Center of the cylinder block (as used in OEM applications)

- Good balance of knock signal pickup from all cylinders

- Best signal to noise ratio

2. Front or back side of the cylinder block

- Reduced sensitivity to one or more cylinders depending on position of sensor

- Possible compromise of signal to noise ratio

3. Cylinder head

- Reduced sensitivity to one or more cylinders depending on position of sensor

- Noise pick up from valve train. Results in worst signal to noise ratio

4. Intake Manifold

- Overall reduced sensitivity. In many cases it should be the second best position choice after the center of the cylinder block

SENSOR MOUNTING TIPS:

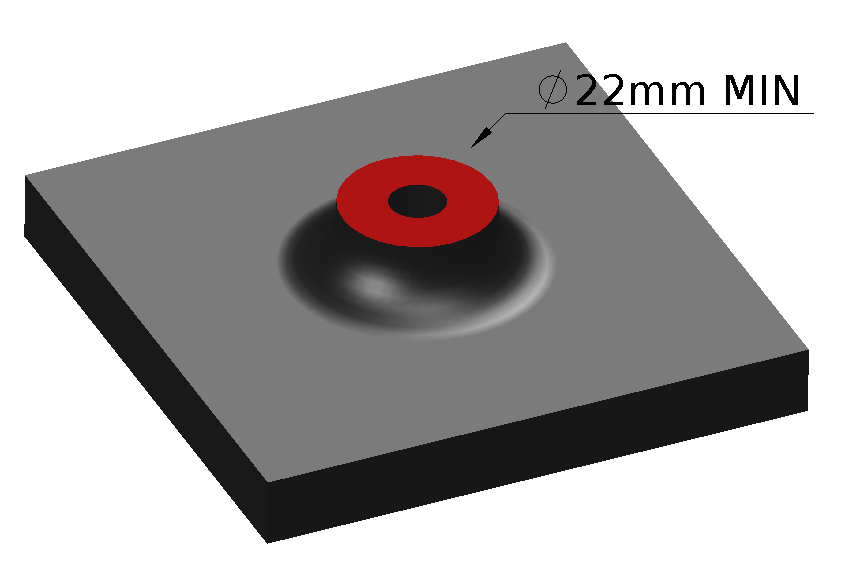

1. The mounting surface must be machined flat and square to the

threaded hole or stud

It must also be at least 22mm in diameter. Why is that? Because a proper contact

surface will ensure that the engine vibration will be transfered to the sensor reliably.

Knock mounting boss dimension

2. When installed only the center metal part of the sensor should

make contact with the engine (red colour)

Knock sensor contact

3. Make sure that the sensor mounting bolt or nut is torqued to

the correct specification.

The common M8 thread requires 20Nm torque.

4. Secure the knock sensor cable a few cm away from the sensor

to prevent unwanted vibrations being transfered to the sensor

If any of the above is not adhered to, the acoustical coupling of the sensor to the engine will be

compromised and the output signal of the sensor will not be reliable for knock detection!